Views: 0 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

You use strong machines every day. A Pillow Block Bearing helps your machines work well. These bearings are simple to put in and take care of. They come ready to use and fit most sizes. You can change them fast. Here are their best features:

Benefit | Description |

|---|---|

Reduced friction | Uses less energy when things spin. |

Easy access | Split housing lets you check and change parts fast. |

Reduced downtime | Modular units switch out quickly, so machines keep working. |

Pillow Block Bearings are simple to put in place. You only need basic tools. This helps save time and money when setting up.

These bearings are used in many fields. They work in factories and on farms. Their flexibility lets them fit different machines.

Pillow Block Bearings are strong and last a long time. They do not wear out or rust easily. They can work for years, even in hard places.

Taking care of them is easy. You just look for dirt and add grease when needed. This helps machines keep working well.

Picking the right Pillow Block Bearing helps machines work better. They lower friction and handle misalignment. This makes equipment last longer.

It is quick to put in a Pillow Block Bearing. The design makes the job simple. You do not spend much time lining up parts. The mounting bracket keeps the bearing steady. It helps you set it up with less work. You can use a support rail for straight alignment. If the shaft is not straight, the bearing can handle up to 0.125 inches off. This saves you time and money.

Tip: You do not need special skills to install a Pillow Block Bearing. Most jobs use basic tools and safety gear.

Tools Needed | Safety Equipment |

|---|---|

Feeler Gauge | Steel-Toe Boots |

Spanner Wrench | Safety Glasses |

Small Punch & Hammer | Gloves |

Ratchet and Socket |

Here are the steps for putting it in:

Slide the seal ring, adaptor sleeve, bearing, lockwasher, and lock nut onto the shaft.

Lift the shaft with a jack to take off pressure.

Use feeler gauges to check the space.

You do not have to take apart the whole housing to change the insert bearing. This design cuts down on downtime and makes fixing things easy.

Pillow Block Bearings work in many industries. Their shape fits lots of machines and setups. You will see them in:

Manufacturing

Agriculture

Construction and Mining

Transportation

Food Processing

Paper and Pulp Industry

Steel Industry

Marine Applications

Automotive equipment

Pillow Block Bearings are good for light loads and low torque. The mounting bracket and insert bearing let the shaft turn freely and stay supported. You can pick split or unsplit types for easy care. Makers offer units for many shaft sizes and load needs. Cast iron and steel help these bearings hold heavy loads.

Pillow Block Bearings have static and dynamic load ratings. You can check these ratings to find what you need.

Strong materials help them hold more weight.

You want your machines to last a long time. Pillow Block Bearings resist wear and rust. You can choose different materials for your needs.

Material Type | Benefits |

|---|---|

Complex shapes, good rust resistance, works for many uses. | |

Cast Iron - Nickel Protection | More strength, toughness, and rust resistance. |

ZDC Alloy with Electroless Finish | Better rust resistance and strength, good for looks and use. |

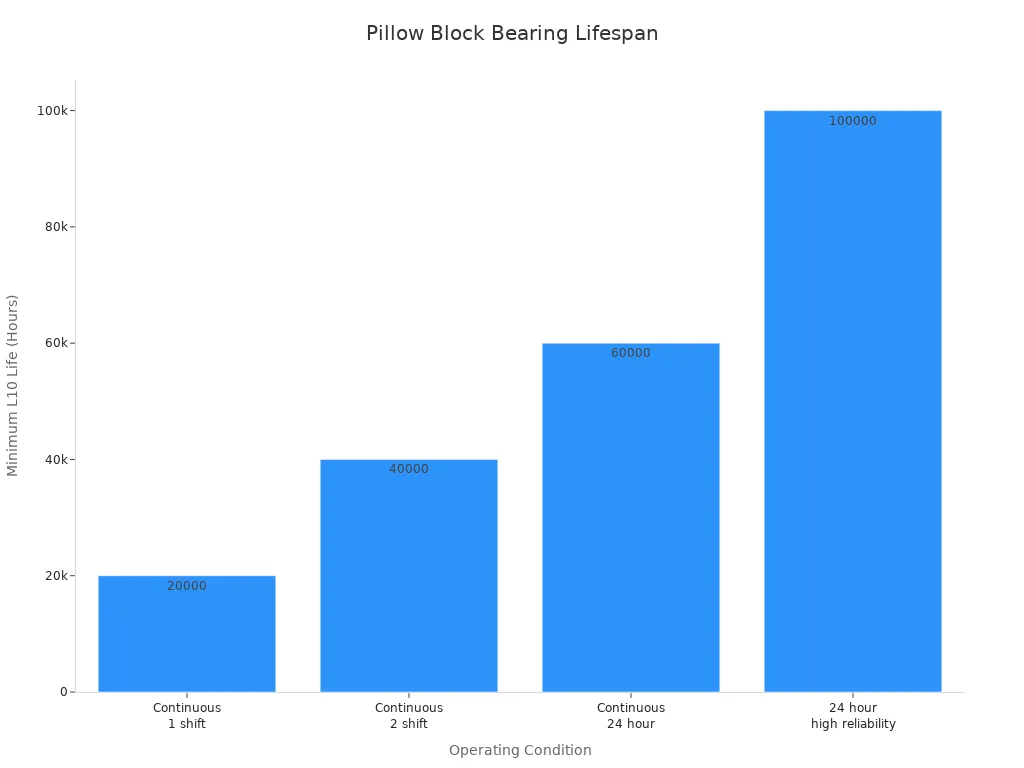

Pillow Block Bearings last for years, even in hard jobs. You can see how long they last in different working times:

Operating Condition | Minimum L10 Life (Hours) |

|---|---|

Continuous 1 shift operation | 20,000 |

Continuous 2 shift operation | 40,000 |

Continuous 24 hour operation | 60,000 |

Continuous 24 hour operation reliability important | 100,000 |

You can trust Pillow Block Bearings for long use. Their design and materials help machines run well and need fewer fixes.

Pillow Block Bearing units are used in many factories. They help machines carry heavy things. These bearings make machines run smoothly. Their shape helps stop shaking, so machines stay safe. Less friction means machines can go faster and last longer. If a shaft is not straight, the bearing can still work. You can add grease easily with fittings. You do not need to take apart the machine to check the bearing.

Benefit | Description |

|---|---|

Handles big weights, keeps machines steady. | |

Reduce Vibration | Lowers shaking for smoother machine work. |

Minimize Friction | Less friction helps machines work better and last longer. |

Accommodate Shaft Misalignment | Can adjust if the shaft is not straight, so it lasts longer. |

Easy Maintenance | Grease fittings make care quick and easy. |

Works for many different factory jobs. |

You see these bearings in presses, pumps, fans, and assembly lines. Makers use cast iron and steel to make them strong. You can pick mounted ball bearings or other types for your needs.

Farmers use Pillow Block Bearing units in their machines. These bearings help farm equipment work in hard places. You see them in machine frames and on conveyor belts. Their design makes it easy to put them in and line them up. This means repairs are faster.

Used in machine frames

Found on conveyor belts

Easy to put in and line up

Pillow Block Bearing units last a long time in tough places. They can handle shafts that are not straight. They carry heavy loads and keep out dirt and water. Your machines last longer because these bearings do not rust and need little care.

Can line up by themselves for smooth work

Can carry heavy loads for good performance

Good seals keep out dirt and water

Lasts longer because it does not rust

Pillow Block Bearing units are in HVAC systems and conveyor belts. These bearings hold the spinning shafts that move belts and fans. They keep shafts straight, which helps things run well. In conveyor belts, the bearing holds the shaft and helps the belt move.

Makers use different materials for these bearings. Cast iron is strong and can hold heavy things. Thermoplastic is light, does not get hurt by chemicals, and works in wet places.

Material | Properties |

|---|---|

Cast Iron | Strong, holds heavy loads, lasts long in hard jobs. |

Thermoplastic | Light, does not get hurt by chemicals, good for wet places. |

You see these bearings in air handlers, blowers, and conveyor systems in factories and warehouses. Their strong build and good materials help machines last longer and need less fixing.

When you look at pillow block bearings and other types, you see some clear differences. Pillow block bearings hold shafts that go the same way as the mounting surface. Flange bearings hold shafts that go straight up and down. Most pillow block bearings use two bolts to stay in place. Flange bearings might use two or four bolts. This makes pillow block bearings easier to put in.

Pillow block bearings hold shafts that are parallel.

Flange bearings hold shafts that are perpendicular.

Pillow block bearings use two bolts to mount.

Flange bearings can use two or four bolts.

Roller pillow block bearings have extra good points. They can run faster and are stiffer. You can put them in even if things are not lined up perfectly. These bearings work well even if there is dirt or dust. They keep working in tough places.

Some types, like Type E pillow block and flange bearings, have extra seals. These seals keep the oil inside and stop leaks. They also keep out dirt. This helps a lot in food factories or places with hard jobs.

Bearing Type | Load Capacity | Ease of Installation |

|---|---|---|

Pillow Block | Usually lower than flange bearings | Easy to install with holes already made |

Flange Bearing | Often higher because of strong mounting | Harder to install because of more steps |

Pillow block bearings help you save money because they do not need much care. You only need to oil them sometimes to keep them working well. Mounted ball bearings need more work. You have to clean them, add oil, and check them often.

Bearing Type | Maintenance Requirements |

|---|---|

Pillow Block Bearings | Only need oil sometimes to work well and stop friction. |

Mounted Ball Bearings | Need lots of care like checking, cleaning, adding oil, and measuring. |

Self-lubricating pillow block bearings stop grease from getting everywhere. You do not spend much on work or oil. Cast iron pillow block bearings also need less care. This makes them good for big machines.

Feature | Cost Savings Benefit |

|---|---|

Self-lubricating design | No grease mess, less work needed |

Longer life in tough places | Fewer changes, saves money over time |

Cast iron construction | Needs less care, great for big machines |

Tip: Pick pillow block bearings if you want less downtime and lower costs. Their simple shape and strong build give you good value for your money.

You want your machines to work well and not stop for long. Sometimes, problems can make your work slow. Here are some issues you might see with machines that spin:

Too much noise and shaking

Getting too hot

Wearing out too soon

Shaft not lined up right

Problems with oil or grease

You can fix these problems by taking care of your machines the right way. Try these steps to help your machines last longer:

Use the right oil or grease to stop rubbing and rust.

Check bearings often so you find problems early.

Line up and balance shafts to stop shaking and wearing out.

Keep dirt away because it can hurt bearings fast.

Put in bearings the right way for best results.

Tip: If you check and clean bearings often, you can stop big repairs and keep your machines working.

When you do these things, your machines stop less. Your equipment stays strong, and you spend less time fixing it.

You can help your machines work better by picking the right bearing. Pillow block bearings help your machines run smooth and last longer. Here is how they make things better in different ways:

Benefit | Description |

|---|---|

Stability | Gives steady support so parts spin smoothly. |

Friction Reduction | Cuts down rubbing, so parts last longer and save energy. |

Misalignment Accommodation | Handles shafts that are not straight, so you avoid damage. |

Easy Installation | Lets you put in bearings fast, saving time and work. |

Maintenance-Free Operation | Some types need little care, so you stop less for repairs. |

Material Variety | You can choose from many materials for your job. |

Load and Speed Adaptability | Works for different weights and speeds in many places. |

You also get stronger bearings and better load support. Here is how pillow block bearings do in performance:

Performance Aspect | Description |

|---|---|

Durability | Made from tough materials like cast iron or steel for long life. |

Load Capacity | Handles light and medium weights, with choices for bigger jobs. |

Suitability for Applications | Fits many uses because of smart design and good features. |

Note: When you use the right bearing, your machines work better, last longer, and need fewer repairs.

You can see how a Pillow Block Bearing helps machines work well. These bearings make parts move smoothly. They help stop too much heat. You can put them on many surfaces easily.

You save money because smart sensors help you watch how things work. IoT features let you find problems early.

You see these bearings in lots of places, like factories and energy plants.

You can choose the size and load that fits your job.

Pick pillow block bearings to keep your machines strong and ready for new jobs. They help your equipment stay safe and work well.

A pillow block bearing is a support unit that holds a rotating shaft. You use it to keep shafts steady and reduce friction. The housing makes installation easy.

You find pillow block bearings in machines, conveyor belts, farm equipment, and HVAC systems. These bearings help parts spin smoothly and last longer.

You check the bearing for dirt and wear. You add grease when needed. You replace the insert if it shows damage. Regular checks help your machines run well.

You can choose pillow block bearings made from cast iron or steel for heavier jobs. These materials give extra strength and longer life.

You find pillow block bearings in many sizes. Manufacturers offer units for small shafts and large industrial machines. You pick the size that fits your job.

Copyright © 2023 Shandong Yunfan Precision Bearing Co., Ltd. All Rights Reserved. Technology by leadong.com